Displays for Medical Applications

By Frank Jammers, Business Development Manager (EMEA) at New Vision Display

Estimated reading time: 5 minutes

Visualization is an important parameter in modern life and nowadays almost exclusively realized by use of Liquid Crystal Displays (LCDs). But not every LCD is equally suited for every application. Each and every employment has specific requirements that have to be met by the display of choice. Engineers, developers, and other decision-makers must have a deep and comprehensive understanding of how display specifications impact final products.

To choose the right display for a medical application, it’s important to know how a display differs from an industrial or consumer display, as well as the benefits realized by these specific features, and how they impact the application. To complicate matters, the medical market comprises of many sub-markets with requirements ranging from small, low-resolution panels (or even passive segmented displays) in rugged and mobile medical applications to large, high-resolution, high-contrast color or monochrome panels for medical diagnostics.

Designing solutions for harsh environments

Displays can be subjected to extreme temperature, shock and vibration, moisture and variable ambient lighting. Those conditions mandate a highly reliable display and possibly the use of a clear protective cover that can safeguard the display from the rigors of daily use. Variable ambient-lighting conditions range from low-level indoor lighting to direct sunlight, in which case peak luminance and high contrast become very important.

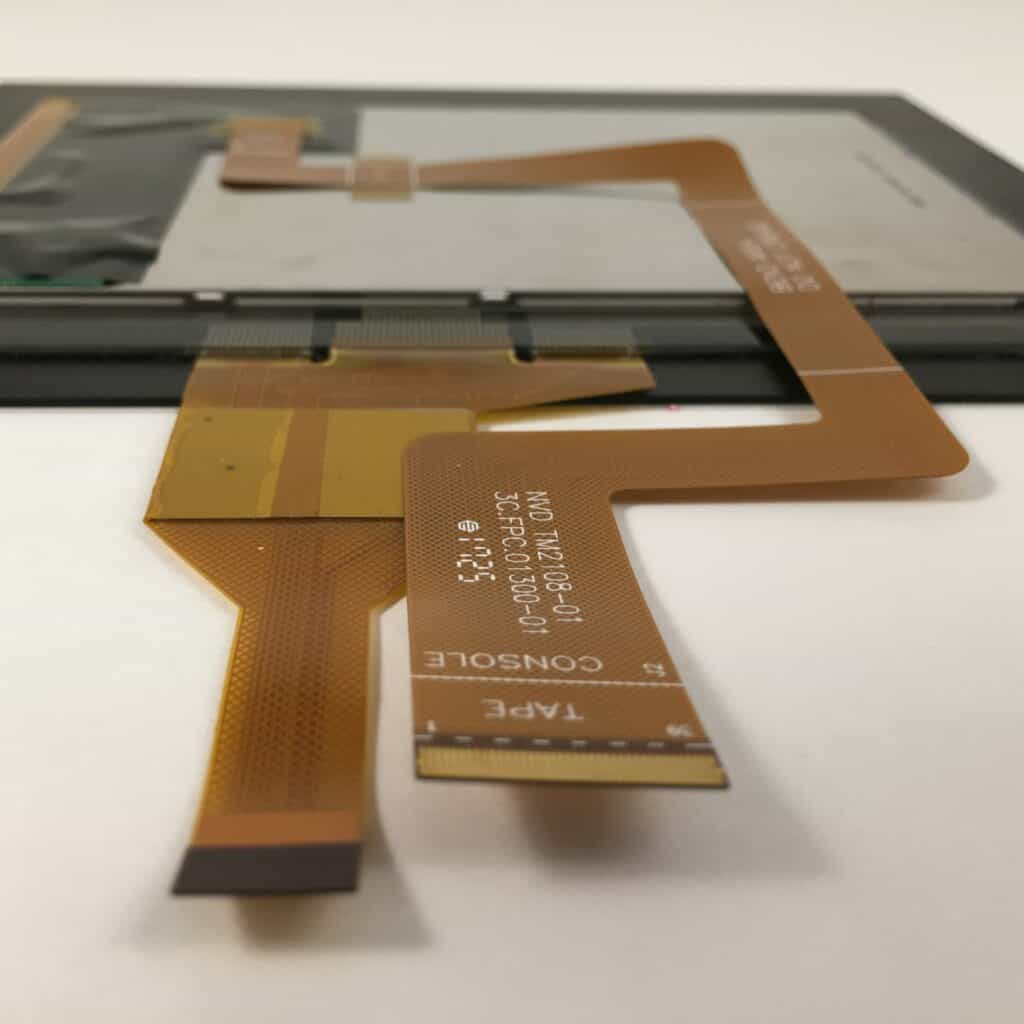

When standard display performance is not sufficient, Medical TFT suppliers can add enhancements such as optically bonded glass with anti-reflective coatings (to provide protection and preserve contrast), which can help significantly. Another option is to use transflective displays that combine both reflective and transmissive properties and are suitable for performance in all ambient lighting conditions.

Wide operating temperature ranges and varying thermal-management conditions must also be addressed since temperature ranges from -10 degrees C to 70 degrees C are not uncommon. For use at elevated temperatures, there are medical displays that include wide-temperature range liquid-crystal materials to combat the effect of solar loading in direct sunlight.

For example, defibrillators designed for emergency medical treatment, air rescue or ambulatory use are exposed to adverse environmental conditions and typically do not require panels with high resolution, high color fidelity or fast response times. The demands are relatively simple because the information to be displayed is simple – maybe several scanned wave-forms and some numerical content.

Even so, the displays need to be power-efficient and mechanically robust, with high reliability, high quality and a small footprint.

Medical standards and approval processes

Medical TFT manufacturers basically distinguish between three classes of medical application with individual requirements:

- Standard (e.g. bedside monitors),

- Life-supporting (e.g. glucose meters or dialysis equipment), and

- Life-critical (e.g. defibrillators or respirators).

These categories have very different demands in terms of product reliability, functionality and mean time to failure (MTTF).

Two widely accepted standards organizations demand even more from display integrators: The European DIN (Deutsches Institut fur Normung eV) body and the American Association of Physicists in Medicine Task Group 18. Both organizations outline measures for acceptance testing, as well as quality control, to ensure consistent display performance over time. The two organizations define acceptable parameters for resolution, noise, glare, color uniformity, geometric distortion, reflection, luminance response, luminance uniformity, and viewing angle.

Long-term availability and backward compatibility

The qualification process for these standards is time-consuming and expensive. Consequently, the device manufacturers are reluctant to modify an approved system and are demanding long-term availability for each component – a requirement which standard or consumer type LCD displays can’t meet. Therefore, clearly defined life cycles in combination with a well-established phase-out policy are mandatory to the successful delivery of LCD displays into medical markets. Product life cycles typically must exceed 5 years, but may be required to exceed 10 years or more.

Backward compatibility, both in electrical and mechanical specifications, can help to save requalification cost when component discontinuation ultimately can’t be avoided. It can also save significant costs for products that need to evolve with the latest technology or require other kinds of upgrades.

System manufacturers often try to avoid customization and NRE investment. But, in many cases, one-time payment provides greater cost benefits compared to successive re-designs. For example, owning a display mask can help secure production over a long period of time: When a display panel manufacturer decides to stop production of a particular LCD cell, the mask can be transferred to another site or different manufacturer, since the tool is the customer’s property.

How NVD can help you find the right medical display solution

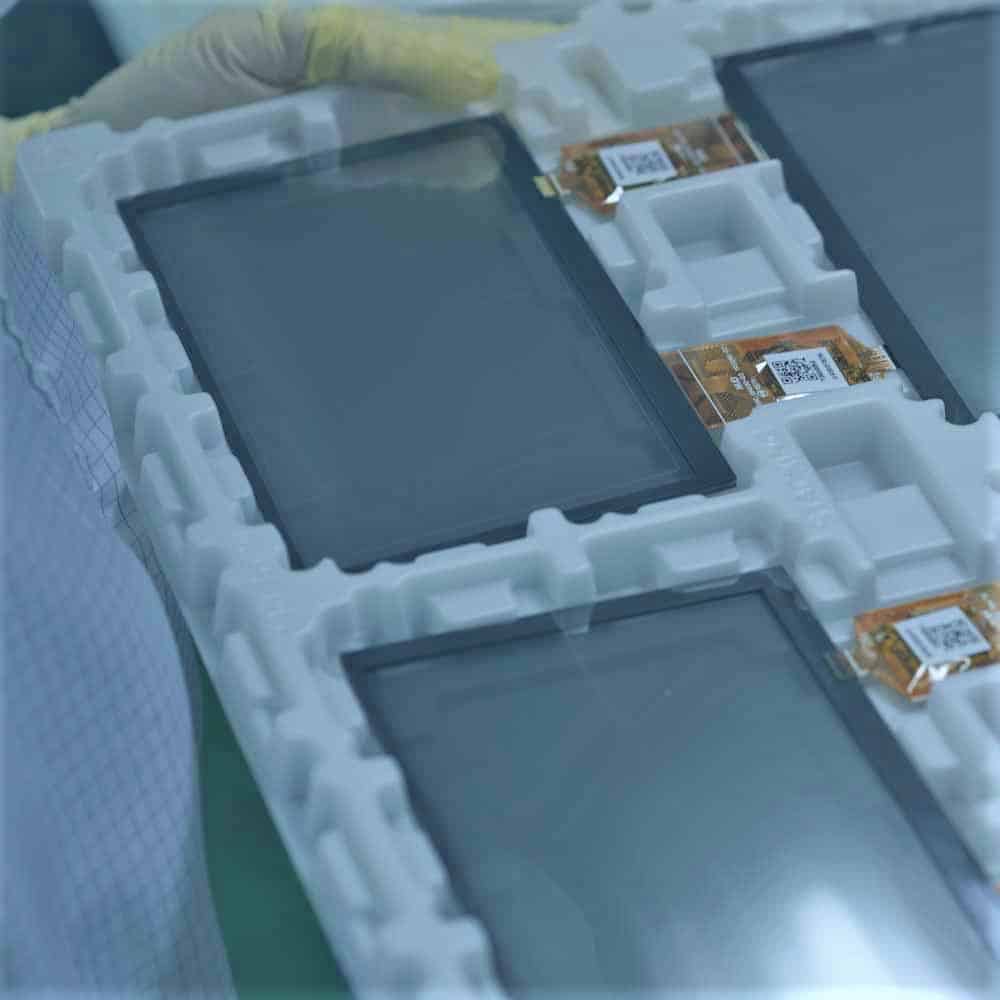

New Vision Display specializes in durable medical device displays that can withstand heavy, daily operation over many years. Whether you need the high resolution, precise imagery or rugged, small form factor medical LCD displays on applications ranging from handheld point of care devices or first-responder gear, New Vision Display can help you identify the right display solution.

For sterile environments, NVD offers solutions that can withstand repeated sterilization and cleanings from a variety of chemical substances. We also offer capacitive touch panel technology that responds accurately and effectively when operated with or without gloves.

The team at New Vision Display has the expertise to meet your exact standards: Sunlight readability, touch integration, optical bonding, anti-reflectance, anti-glare, anti-fingerprint, anti-microbial coatings and much more.

Please reach out us at sales@newvisiondisplay.com or via the contact form below.