Display and touch system integration

By Frank Jammers, Business Development Manager (EMEA) at New Vision Display

Estimated reading time: 5 minutes

Evolution of the Human Machine Interface (HMI)

Years ago, machine user interfaces were comprised of separate displays and data input terminals. In today’s modern equipment we now see both the input and output units merged into a single, streamlined device; best known as the Human Machine Interface (HMI).

This article explores some of the components and processes used within modern day HMIs.

Traditional keyboards were replaced some time ago by a combination of a touch panel and soft buttons. These touch panels were initially mostly made with resistive touch technology, but now trend towards projected capacitive touch technology (PCAP) since the introduction of smartphones. PCAP technology enables data input with bare fingers – no pen or stylus required – and can respond to simultaneous touches (i.e. multi-touch), enabling zoom and swipe gestures.

Protective Cover Lenses – Materials & Benefits for HMIs

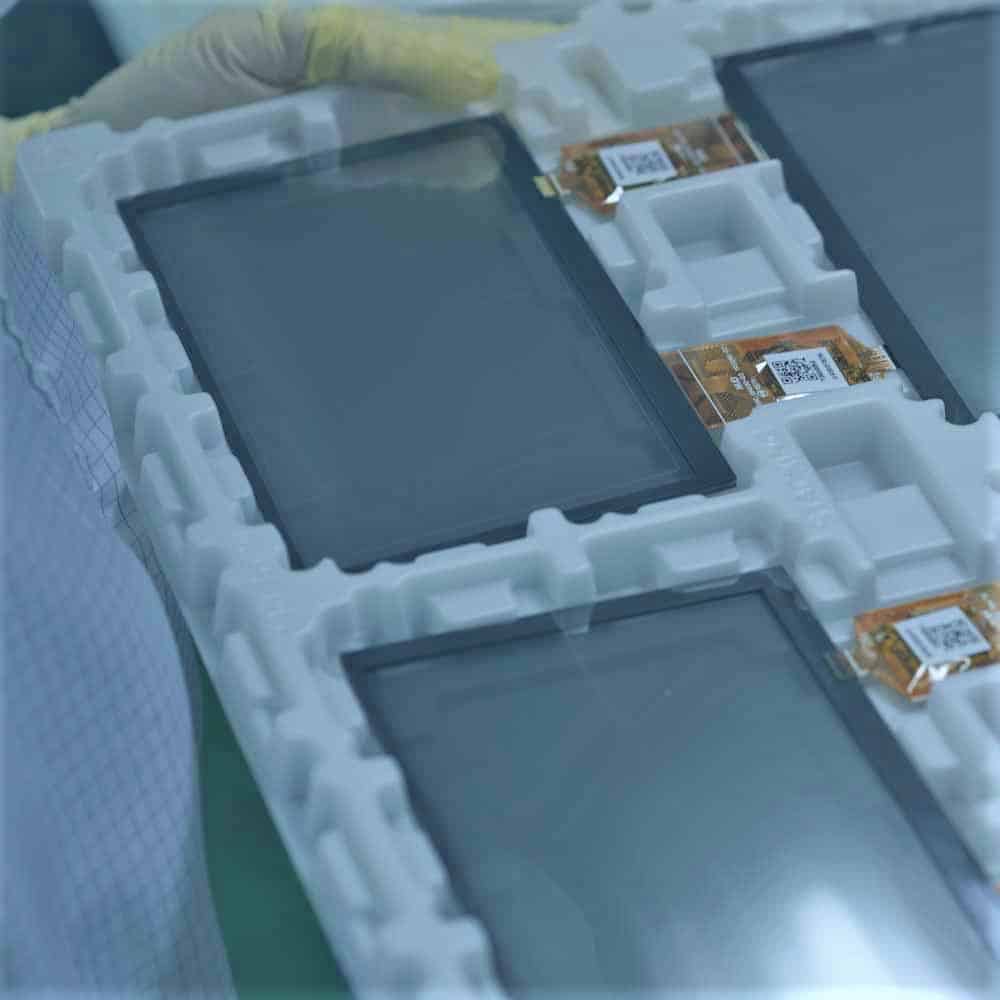

A PCAP touch panel can be designed using many different stack-ups, but what they all have in common is a protective cover lens as the top surface layer.

Although polycarbonate is a popular material, most lenses are now made of hardened glass due to its superior scratch resistance. Certain glasses can be chemically strengthened to provide excellent break and scratch resistance, plus modified to resist fingerprints, dirt, and oils – all popular features for industrial, medical and automotive environments. Corning® Gorilla® Glass is one familiar example of chemically strengthened front glass material.

In addition to protection, front glass offers some cosmetic functionality. The rear side of the cover lens which faces the display can be imprinted with special ink, giving the HMI front a sleek appearance. This can include intuitive symbols, icons, Android buttons or company logos. They can be printed in different colors for an even more eye-catching look.

HMI Stack-up Bonding Techniques & Materials

A variety of techniques and materials are available for merging the cover lens, PCAP touch sensor and LCD or OLED display together. Each directly impacts the system cost, robustness and optical performance of the HMI unit. NVD has assisted numerous customers in determining the optimum combination for their technical and financial needs.

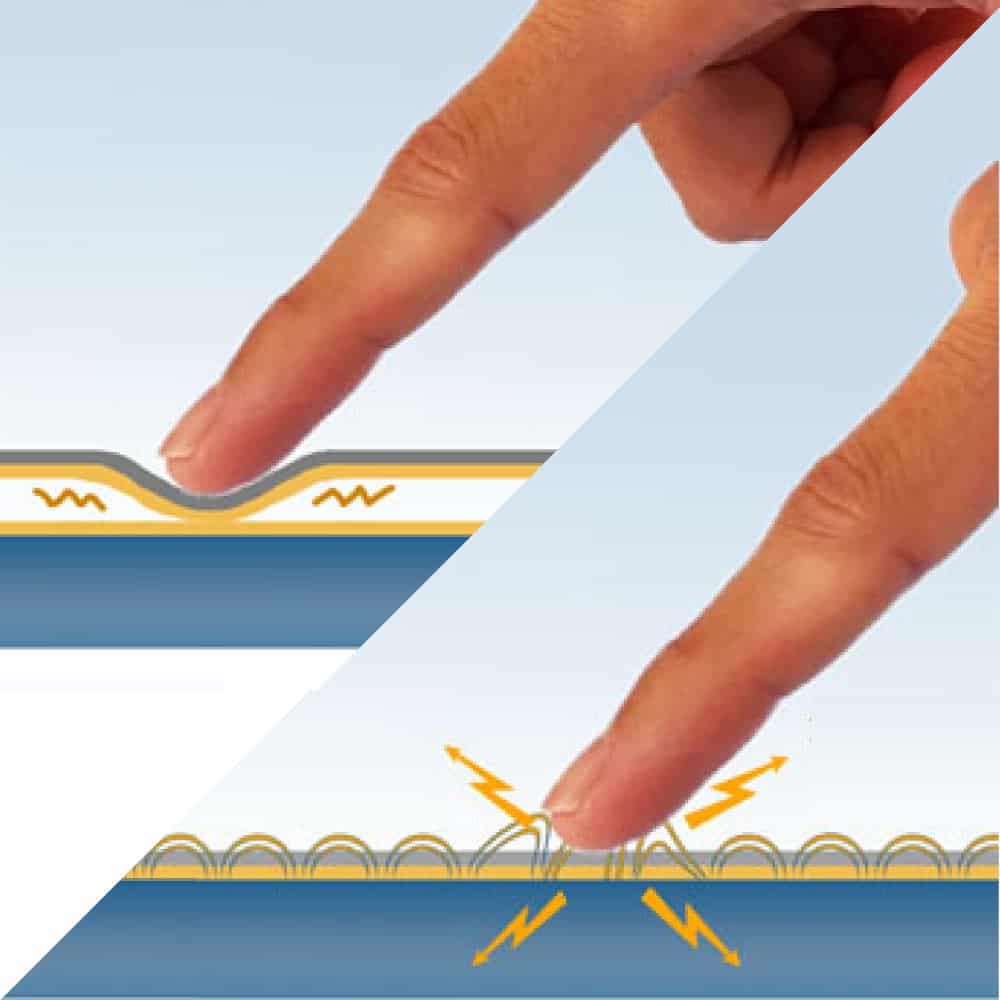

While front lenses and PCAP touch sensors are almost always tightly laminated together, there is more versatility in how the PCAP touch sensor and the display unit are bonded together. The two can be filled or, alternatively, mounted with an air gap between them.

Air Gap Bonding Method (PCAP Sensor to Display)

The air gap mounting method is both cost-effective and easy, using double-sided adhesive tape to bond the display frame and touch panel together. One of its significant benefits is that the layers can be disassembled for re-working or exchanging components – in case of field failures and assembly errors – instead of needing to replace the whole system. The disadvantage is that light can be reflected within the air gap, impacting – and in worst case, even preventing – the readability of the screen (e.g. in direct sunlight). NVD can propose unique solutions which minimize light reflection issues – a common budget versus performance concern in product design.

Optical Bonding Method (PCAP Sensor to Display)

The truest image quality and touch responsiveness of an HMI unit can only be achieved via optical bonding. This filling technology eliminates the air gap through either liquid glue or a thin, optically neutral adhesive film. The filling material is selected to exactly match the refractive indices of the surrounding components – glass, polycarbonate, PET – so that it appears invisible. Unlike the air-gap method, components joined in this way cannot be separated for repair or replacement purposes. But this disadvantage turns into a benefit when the system is required to fulfill certain standards such as avoidance of chips, splinters, and sharp particles. Optically bonded touch panels with a glass surface can be designed to meet the automotive head-impact test requirements, while air-gap solutions often require plastic lenses or additional measures.

Benefits of Working with New Vision Display

Previously, touch and display system designers needed to do a lot of research and investigation when selecting individual components and different vendors. They were required to either educate themselves or find knowledgeable service providers and had to qualify the assembly to assure components worked together properly and reliably. With today’s availability of complete HMI systems from one single source, this costly and time-consuming process has been streamlined.

As a specialist in optoelectronic components, New Vision Display excels in delivering custom solutions, complete with:

End customers will receive an assembly exactly tailored to their demands with clear specifications and NVD’s warranty on the assembly as a whole unit.

NVD has an experienced team ready to help you identify the best solutions for your needs. Please reach out us at sales@newvisiondisplay.com or via the contact form below.