Transflective LCDs – A Sunlight Readable Solution

By Frank Jammers (FAE for Europe) and Matthias Pfeiffer (CTO) at New Vision Display

Estimated reading time: 5 minutes

Table of contents

For many years now, transmissive TFT displays have been the dominating technology in visualization. With more and more screens being used outdoors and in portable applications, sunlight readability has become a critical factor in the display market. One way many LCD manufacturers address this issue is to increase the display’s backlight luminance. Although this works well for many applications, it also increases the power consumption and bulkiness of the display making it a non-ideal solution for some portable or small-size applications.

As an alternative to high-brightness TFTs, New Vision Display offers transflective TFT solutions which offer readability in any lighting condition without increasing power consumption or bulkiness. However, the more complex structure of transflective displays increases the manufacturing costs.

Transflective TFT cell architecture

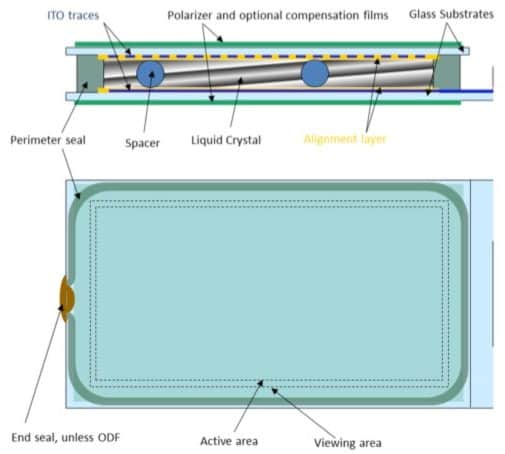

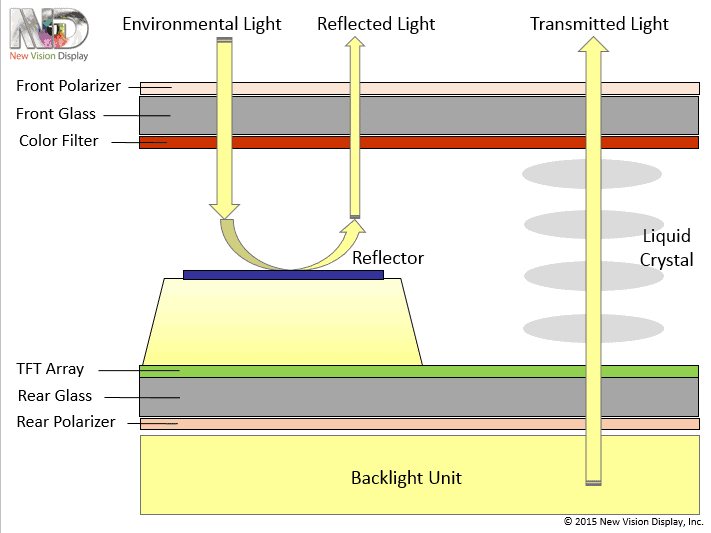

Simple, low-resolution LCDs routinely are offered in reflective, transmissive, and transflective (partially transmissive and partially reflective) modes. This is achieved simply by choice of the reflector behind the display, which is usually attached to the rear polarizer. This method is not feasible for TFT displays due to the inherently much lower transmission of these devices.

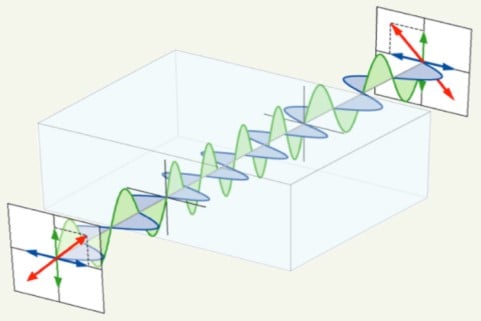

Transflective TFT displays have a unique cell architecture compared to standard TFT display modules. This is necessary to accommodate for the fact that, in transmissive mode, light passes only once through the liquid crystal layer before reaching an analyzer, while in reflective mode it passes the liquid crystal layer twice.

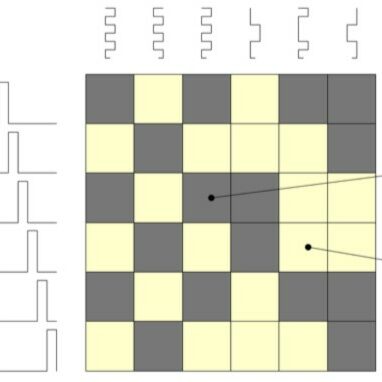

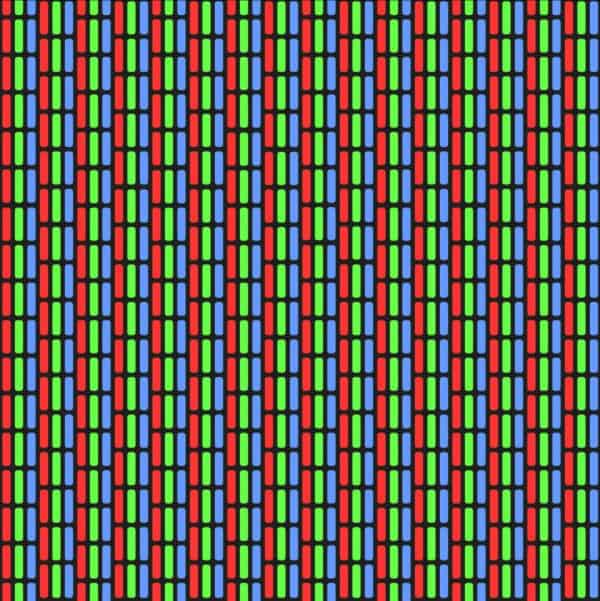

In the transflective cell architecture, every single pixel is divided into a transmissive and a reflective section. The reflective sections are based on a polymer film with micro-metal mirrors within the glass cell. The size and partition of both transmissive and reflective sections are flexible and depend on the desired focus of the final display. Typically, the liquid crystal layer thickness in the reflective part is only half of the cell gap in the transmissive part. The front polarizer acts as both polarizer and analyzer for the reflective portion of each pixel. This requires selection of a liquid crystal mode that works with parallel polarizers, unlike transmissive displays where the polarizer and analyzer are usually crossed. Furthermore, in order to achieve satisfactory picture performance in reflective mode, the front surface reflection must be suppressed, which is achieved by coating an anti-reflective or an anti-glare layer on the front polarizer.

How do transflective TFTs work?

Within transflective LCDs, transmissive and reflective modes work together for enhanced performance:

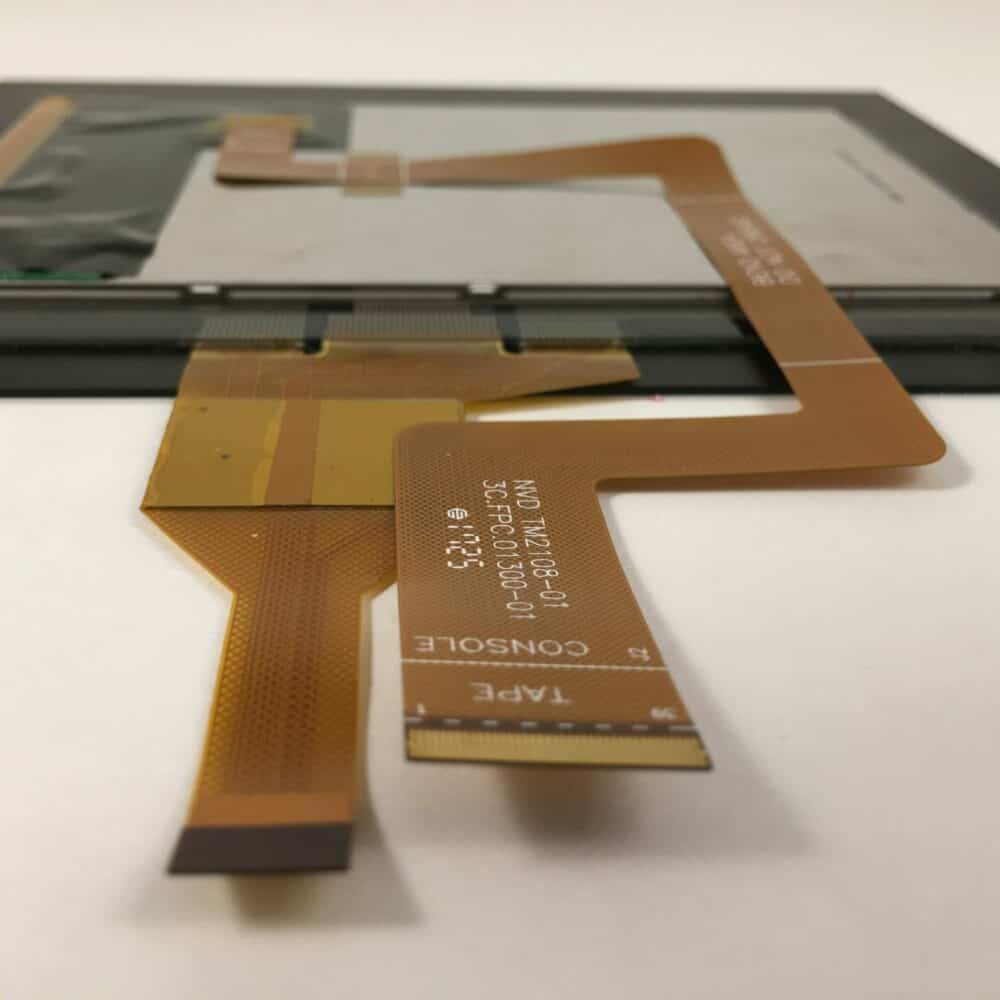

- In dimly lit environments, the display’s transmissive mode is dominant: Light emitted from the display’s backlight illuminates the display image for the viewer (see Image 2 below).

- In bright environments, such as direct sunlight, the display’s reflective mode is more dominant: The display image is illuminated via bright ambient light reflected off the internal mirror structure, rather than emitted light from the module’s backlight (see Image 3 below).

The reflective mode thereby provides tremendous power savings, an especially useful feature for battery-operated devices such as mobile terminals and handsets.

Image 2: Transflective display in dim light

Image 3: Transflective display in bright sunlight

NVD’s transflective TFT display manufacturing capabilities

The major difference to other manufacturer’s transflective LCD products is that NVD combines the sunlight readability with its wide viewing angle technology, Amplified Intrinsic Fringe-Field (AIFF), which is a variation of Multi-Vertical-Alignment (MVA). The result is stunning viewing angles of typically 80 degrees into all four directions and under all environmental light conditions.

The contrast ratio in reflective mode is still 30:1 versus 300:1 in transmissive mode. Color gamut is specified with 60% coverage of the NTSC triangle and the liquid crystal’s response time is 30ms from black to black.

The operating temperature range is designed at -30 to +80 degrees Celsius. Storage temperature is even larger from -40 to +90 Celsius so that the product easily complies with outdoor and industrial requirements. 2”, 3.5” and 4.3” are pre-tooled.

Transflective LCD applications

Transflective TFT display modules can be manufactured in a wide range of sizes and for diverse applications. NVD focuses its efforts in transflective displays on portable applications, currently up to 4.3 inches with resolutions in the 230ppi range. Other sizes are available as custom designs.

Target applications for transflective TFTs – to name a few – include mobile payment terminals, credit card readers, portable monitors, navigation devices, diagnostic equipment, outdoor recreational products, medical products, and high-end appliances.

Looking for guidance? NVD can help.

Call one of our LCD experts to discuss your project, or complete the below contact form and we’ll put you in touch with the right representative. We look forward to helping you choose the right display solution for your application.