Understanding AR, AG, and AF Glass Treatments

Estimated reading time: 4 minutes

From an early age, the consumer experience is being shaped by the products we use on a daily basis. Smartphones, tablets, and other products with touch screens have forever changed the way we interact with devices. They’ve become so commonplace that everyone, even toddlers, expect many screens (TV screens included) to have touch screen interfaces.

As you work with your touch screen display manufacturer to design your touch-enabled product, a few acronyms might have crossed your desk: AR, AG, AF, and AS. What do these acronyms mean and how will they work into your designs and the consumer experience? Let’s explore the differences.

Anti-Reflective (AR) Glass Treatment

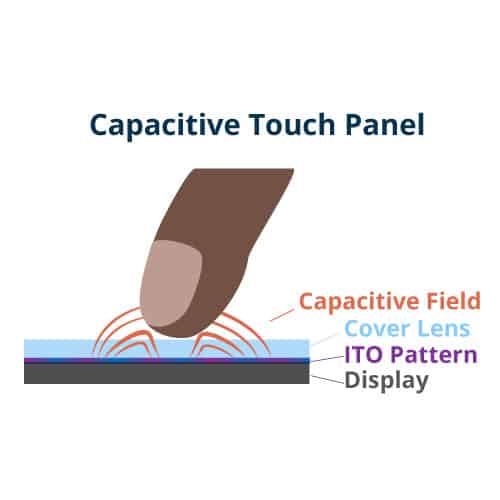

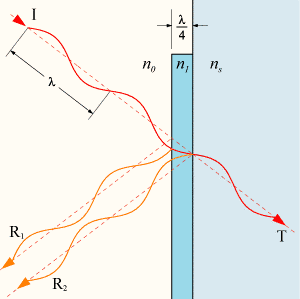

Anti-reflective glass treatment involves applying a film or coating of a specific thickness to the surface of a cover lens.

The film reduces the reflections on the surface by canceling out a specific wavelength of light as it is reflected back to the consumer. When a specific wavelength of light passes through the AR material, some of it is reflected back to the consumer at the surface of the AR film (R1) and some of it is reflected at the surface of the cover lens (R2). The thickness of the AR film causes the reflected wavelengths (R1, R2) to be reflected exactly out of phase with each other (see diagram 1.1) so that they cancel each other out. Thus the consumer will not see their own reflection. Instead, they will see a brighter and more vivid display.

Anti-Glare (AG) Glass Treatment

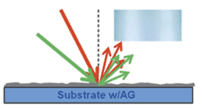

Anti-glare glass treatment involves creating a rough surface on the cover lens via an etching process.

As light reflects off of the rough surface, it is scattered at different angles (see diagram 1.2) which reduces the clarity of the reflected image. Thus, the consumer will not see the bright glare of any reflected light source.

Anti-Finger Print (AF) or Anti-Smudge (AS) Glass Treatment

Anti-fingerprint glass treatment (also known as anti-smudge glass treatment) reduces the ability of the cover lens retaining oils from your finger.

AF/AS treatment is typically applied by vacuum deposition or by a liquid chemistry process, which creates an oleophobic top coating. Since this layer is a chemical modification of the glass surface, it is very durable compared to aftermarket AF/AS spray-on films.

It has to be noted that AF/AS glass treatments do not perfectly prevent fingerprints. They only cause finger oils to bead on the surface, which makes them less noticeable and also much easier to clean off the screen.

Another benefit of the AF/AS coating is the “feel” or user perception of the treated surface. Because the surface is smooth, the finger will glide more easily compared to a non-treated surface. A non-treated cover lens surface can cause the user’s finger to stick, skip, feel like it’s being dragged, or even make drawing a singular line on the screen difficult so that it becomes a dotted line.

Not all treatments can be combined. Please contact our experienced sales and technical staff to determine which treatment is best for your application.